Our range of Pail & Bucket Printers

Desco Pail Printers are designed to provide high-speed continuous production. Desco's renowned high quality of construction, combined with industry leading dry offset printing heads, has always offered the ultimate in high quality and reliability for the production of all types of artwork onto buckets, pails and similar shaped containers.

Models are available to suit all levels of production requirements and every machine is available with a range of options that cannot be matched by any other manufacturer. Every machine is offered with a variety of different product handling solutions to suit individual requirements for automated feeding, nesting, de-nesting, stacking, etc. Each model is optionally available with UV drying on Mandrel (UVM).

Whatever your requirements, whether for round, oval, square or rectangular pails, Desco have the best solutions available anywhere. Every machine is customized to meet each customer's individual specifications to provide a perfect fit for your production needs.

The most effective combination of pail printer & accessories for your application can only be determined by analysis of your specific pail printing requirements. Based on our global experience of over 300 machine installations, we can supply the right solutions.

Features & Benefits

Standard Features & Benefits

| Item | Feature | Benefit |

|---|---|---|

| 1. | Welded Steel Machine Base & Blanket Tower | Rigid integrated structure prevents any flexing or movement of the print carriage assemblies to ensure flawless print accuracy. |

| 2. | Positive Timing throughout the Machine | As a helical gear driven machine, there are less wear and tear related issues which are typically associated with timing belts and chains. |

| 3. | Flame Treating System (adjustable flame length 6-12 inches) | Provides ideal levels of pre-print surface tension in the substrate material to ensure a receptive surface and optimum ink adhesion. |

| 4. | Adjustments for Print Angle, Print Height & Print Pressure | Print system is easily and quickly adaptable for different sizes of container, reduces downtime. |

| 5. | Accurate Registration Printing in up to 4, 6 or 8 Colors depending on machine type | High quality printing without variation from product to product. |

| 6. | All Printing in One Pass – Line, Halftone, Full Process or any combination | All colors are transferred to the product in a single rotation of the offset blanket drum, thus guaranteeing registration and quality. |

| 7. | Large Diameter Form Roll to Eliminate Ghost | Prevents inconsistencies in inking densities caused by the inadequate ink transfer ability of smaller diameter form rolls, ensures better overall print quality. |

| 8. | Anti-Backlash Plate Cylinder Gearing all Helical Gears | Eliminates any gear marking or inconsistencies in print due to imperfect gear adjustments, providing a higher printing quality. |

| 9. | Micro Axial & Radial Plate Cylinder Adjustments | Allows fast and precise adjustments for registration between colors when setting up new artworks, reduces downtime. |

| 10. | Swing-Away Ink Roll Sections | Provides easy access for operators for plate mounting and for cleaning, saving time and effort. |

| 11. | Variable Speed Ink Fountain Roll Drive Motor | Ensures totally consistent ink transfer every time the dance roller operates to add ink to the print head distribution rolls, provides better quality printing. |

| 12. | Swing Control Panel | Allows the operator to monitor and control the machine from different positions as required, saving time and effort. |

| 13. | Full Electronic Control & Systems Monitor through PLC with Diagnostic Display | Provides operators and technicians with all the necessary information and controls to run and service the machine successfully. |

| 14. | Heavy Duty Index Cam | Provides precise indexing, stability during the printing operation and the durability required for 24/7 operation for years to come. |

| 15. | Safety Shielding & Guarding | Prevents accidents – meets statutory requirements. |

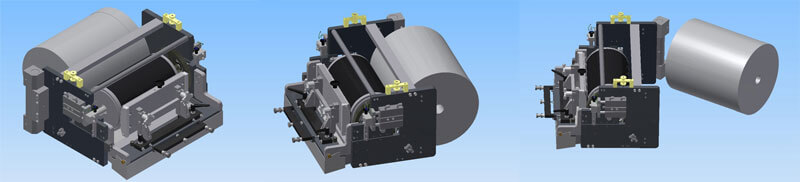

DSP-4 Four color

DSP-4 Four Color Pail Printers

The DSP-4 is our most economical and simplest system to operate and will provide consistently superior quality printing on your pails for a very low investment for many years. If your goal is to print no more than four colors on your pails and have the ability to add automation at a later date, the DSP-4 is an ideal system that will meet your requirements.

• Economical 1 to 4 Color

• 1 to 6 Gallon Pails

• Round, Oval, Square & Rectangular

• Full range of Options available

• DSP-4 Standard - Drying on Conveyor

• DSP-4-UVM with UV Drying on Mandrel

Specifications |

DSP-4 |

DSP-4-UVM |

| Maximum Colors | 4 | 4 |

| On Mandrel UV Drying | No | Yes |

| No. of Mandrels | 4 | 6 |

| Weight of printer | 5,000 lbs (2,268 kg) | 7,500 lbs (3,400 kg) |

| Diameter / Part Taper | Diameter: 14" (350mm) max. • Part Taper: 15° max. | |

| Maximum pail height | 18" (460mm) max. | |

| Printing Height & Length | Height: 12" (304mm) max. • Length: Magnetic Plate Drum: 37.5" (952mm) - max. or Pin Bar Plate: 34.5" (876mm) - max. | |

| Pail Sizes | From 1 to 6 Gallon (3.785 to 25 litre) Pails - solutions available for Round, Oval, Square and Rectangular | |

| Power requirements - Printer | All standards catered for based on Customer’s Requirements | |

DSP-6 six color

DSP-6 - Six Color Pail Printers

The DSP-6 is our mid-range pail printing system and is capable of printing in up to six colors on pails of varying sizes. The DSP-6 will provide you with consistent service on a day-to-day basis for many years, and since all our systems are built with a “building block” concept, it can be automated in various ways, either when initially purchased, or at any time in the future. These automation options can increase production efficiency, lower labor costs, and meet your specific production requirements.

- 1 to 6 Color capability including FlexapexTM option

- 1 to 6 Gallon Pails

- Round, Oval, Square & Rectangular

- Full range of Options & Ancillary Equipment available

- DSP-6-UVM model with UV Drying on Mandrel

Specifications |

DSP-6 |

DSP-6-UVM |

| Maximum Colors | 6 | 6 |

| On Mandrel UV Drying | No | Yes |

| No. of Mandrels | 4 | 6 |

| Weight of printer | 15,000 lbs (6,800 kg) | 18,000 lbs (8,160 kg) |

| Diameter / Part Taper | Diameter: 14" (350mm) max. • Part Taper: 15° max. | |

| Maximum pail height | 18" (460mm) max. | |

| Printing Height & Length | Height: 12" (304mm) max. • Length: Magnetic Plate Drum: 37.5" (952mm) - max. or Pin Bar Plate: 34.5" (876mm) - max. | |

| Pail Sizes | From 1 to 6 Gallon (3.785 to 25 litre) Pails - solutions available for Round, Oval, Square and Rectangular | |

| Power requirements - Printer | All standards catered for based on Customer’s Requirements | |

DSP-8 Eight Color

DSP-8 - Eight Color Pail Printers

The DSP-8 is capable of printing in up to eight colors, including half-tones, fine line, full process or any combination required. It is modular in design and many different features and types of automation can be incorporated in the system to meet your production demands, either now or at a later date.

The DSP-8 is our top of the range “work horse” and will continually provide superior quality trouble-free decorating of your pails for many years. It is sure to become the busiest and highest producing machine in your facility. The DSP-8 can be supplied with UV Drying on Mandrel (UVM).

- 1 to 8 Color capability including FlexapexTM option

- 1 to 6 Gallon Pails

- Round, Oval, Square & Rectangular

- Full range of Options & Ancillary Equipment available

- DSP-8-UVM model with UV Drying on Mandrel

- Solid mandrels

Specifications |

DSP-8 |

DSP-8-UVM |

| Maximum Colors | 8 | 8 |

| On Mandrel UV Drying | No | Yes |

| No. of Mandrels | 4 | 6 |

| Weight of printer | 18,000 lbs (8,160 kg) | 27,000 lbs (12,250 kg) |

| Diameter / Part Taper | Diameter: 14" (350mm) max. • Part Taper: 15° max. | |

| Maximum pail height | 18" (460mm) max. | |

| Printing Height & Length | Height: 12" (304mm) max. • Length: Magnetic Plate Drum: 37.5" (952mm) - max. or Pin Bar Plate: 34.5" (876mm) - max. | |

| Pail Sizes | From 1 to 6 Gallon (3.785 to 25 litre) Pails - solutions available for Round, Oval, Square and Rectangular | |

| Power requirements - Printer | All standards catered for based on Customer’s Requirements | |

Options & Ancillary Equipment

Options & Ancillary Equipment

| Options | DSP-4 | DSP-4-UVM | DSP-6 | DSP-6-UVM | DSP-8 | DSP-8-UVM |

|---|---|---|---|---|---|---|

| Flexapex™ Near Silkscreen Print Quality Color Heads | Yes | Yes | Yes | Yes | Yes | Yes |

| Automatic Feeding System with Inventory System | Yes | Yes | Yes | Yes | Yes | Yes |

| DESCO Automatic Feeder System with Vacuum Pick-Off | Yes | Yes | Yes | Yes | Yes | Yes |

| Solid Mandrels – Quick Changeover | Yes | Yes | Yes | Yes | Yes | Yes |

| Adjustable Mandrel System – Adjusts to Variable Sidewall Thickness, 3 Gallon and up | Yes | Yes | Yes | Yes | Yes | Yes |

| Air/Vacuum Hold-On System | Yes | Yes | Yes | Yes | Yes | Yes |

| Pre-Orientation System, minimizes stress to handle lugs | Yes | Yes | Yes | Yes | Yes | Yes |

| Orientator System, permits printing in register between handle lugs | Yes | Yes | Yes | Yes | Yes | Yes |

| Special Ink Roll System with 12-Inch Form Roll | Yes | Yes | Yes | Yes | Yes | Yes |

| Magnetic or Mechanical Handle Holders | Yes | Yes | Yes | Yes | Yes | Yes |

| Vacuum Destaticizer | Yes | Yes | Yes | Yes | Yes | Yes |

| Magnetic or Clamp Style Plate Cylinders | Yes | Yes | Yes | Yes | Yes | Yes |

| On/Off Form Roller & Plate Cylinder Control by PLC | Yes | Yes | Yes | Yes | Yes | Yes |

| Running Registration for quick print adjustment | Yes | Yes | Yes | Yes | Yes | Yes |

| Ultraviolet or Infrared Curing Conveyor System | Yes | No | Yes | No | Yes | No |

| Automatic Restacker and Inventory System | Yes | Yes | Yes | Yes | Yes | Yes |

| Computerized Control System (CCS) | Yes | Yes | Yes | Yes | Yes | Yes |

| Computerized Product Sizing System, product height, taper & diameter | Yes | Yes | Yes | Yes | Yes | Yes |

| Clearcoat Station with second UV Dryer | Yes | Yes | Yes | Yes | Yes | Yes |

| Corona Treater | Yes | Yes | Yes | Yes | Yes | Yes |

| No Pail No Print | Yes | Yes | Yes | Yes | Yes | Yes |

| PICS Ink Distribution System - replaces normal ink fountain | Yes | Yes | Yes | Yes | Yes | Yes |

| Auto agitator for ink fountain | Yes | Yes | Yes | Yes | Yes | Yes |

| Auto Inspection Station | Yes | Yes | Yes | Yes | Yes | Yes |

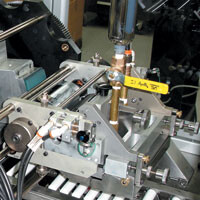

Flexapex®

Flexapex® - near silkscreen quality offset print

Flexapex® combines the benefits of flexographic and offset print technologies. It utilizes UV cured liquid inks and permits the laying down of up to 5 times the amount of ink that is possible with conventional dry offset printing, enabling the transfer of substantially heavier ink films.

Flexapex® combines the benefits of flexographic and offset print technologies. It utilizes UV cured liquid inks and permits the laying down of up to 5 times the amount of ink that is possible with conventional dry offset printing, enabling the transfer of substantially heavier ink films.

Flexapex® allows improved solids and more definite, crisper images wherever density is needed. A further benefit of the Flexapex® process is highly predictable quality and density repeatability on re-runs.

Flexapex® conversion print heads are available as an option on new machines and as a retrofit for existing machinery in the field.